The KW Damping and Valve Technology, 3-Way

KW's adjustable dampening technology is offered for a wide selection of applications and vehicle categories.

Damper Basics - The function of a shock absorber

The primary job of a shock absorber is to subside vibrations caused by the wheels, axles, and body. The technically correct name for it would be a vibration damper. When driving over irregularities, the force generated or vibrations that are created should be absorbed by the suspension. A proper working damper should prevent the following:

- Excessive body motion or roll during bumps or irregularities

- Nose lifting and diving during acceleration or braking

- Wheel bouncing or losing contact with the ground

- Loss of stability or traction during braking

- Loss of control in turns because of low traction

The shock absorbers used in vehicles are usually twin-tube dampers or mono-tube dampers. A piston moves in an oil-filled cylinder in both damper types. The piston forces the oil through the valves, which creates resistance to the oil flow with the help of various holes and orifices.

During rebound, the oil flows from the outer tube back into the inner tube. In addition to the channels in the bottom valve, the oil also has to flow through the rebound valve located at the piston rod, to get into the piston housing.

The Functioning of a KW Twin-Tube Shock Absorber

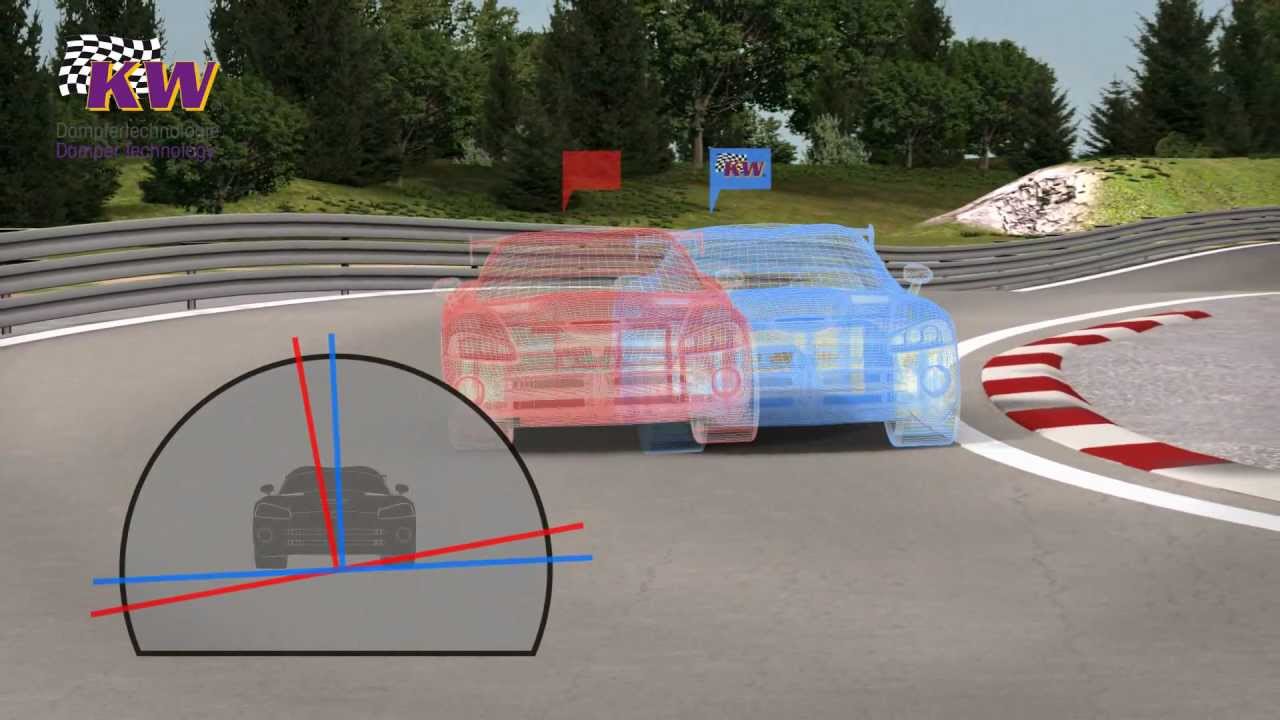

The dampers job in the suspension system is to convert the kinetic energy of the suspension spring into heat energy and dissipate it into the environment. When driving around a right hand curve, the KW coilover kit works in the compression phase on the left side of the vehicle and rebound phase on the right side of the vehicle.

Rebound Adjustment

Independently adjustable rebound damping

Rebound adjustment with an allen key

Rebound adjustment with the KW adjustment knob, when space allows

Rebound adjustment with an integrated adjustment dial

16 Clicks - Best Perfomance and easy Adjustment

All KW coilover kits that utilize KW's TVR-A (Twin Valve Rebound - Adjustable) technology which provides 16 clicks of independent rebound adjustment.

Rebound adjustments can be made to reflect more dynamic driving characteristics or complement a change in tire selection like a different set of wheels or winter tires.

The adjustable rebound feature allows the user to dial in a more sportier tighter handling characteristic or a more compliant comfortable setting.

Technical Details of Adjustable Rebound Damping

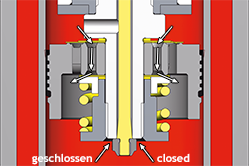

Oil flow during high rebound setting

Bypass orifice with high rebound force position. Digressive damping characteristic and the maximum achievable rebound damping. Damping is determined by the setup specific preload of the valve spring in the piston.

The result:

A firm but not a hard rebound stroke, more resistant to rolling and pitching motions.

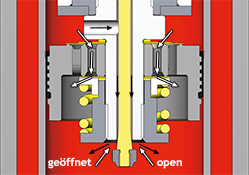

Oil flow during low rebound setting

Bypass orifice with open adjuster position allowing for a progressive damping characteristic and ability to achieve minimum possible rebound damping .The bypass oil volume (black arrows) is reduced for the spring preloaded valve on the piston and the damping forces are therefore reduced.

The result:

A lower rebound damping increases the driving comfort.

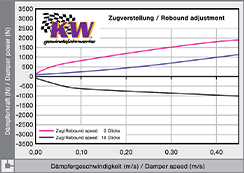

Graphic representation of the relation from damper speed (m/s) to damping force (N) when adjusting the rebound damping.

Compression Adjustment

Independent High Speed & Low Speed Adjustability

KW TVCLH-A (Twin Valve Compression Low High - Adjustable) technology allows for separate and independent damping force adjustment for rebound damping and compression damping in low speed and high speed.

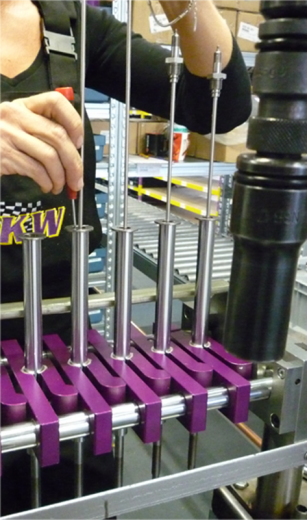

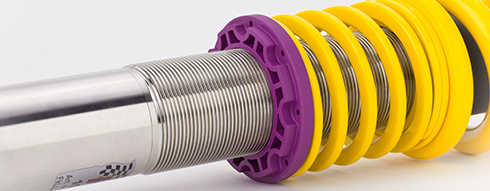

Individual damping force adjustment with color anodized adjustment wheels - with distinct tactile clicks

Preset out of the box from KW with adjustment range in both directions

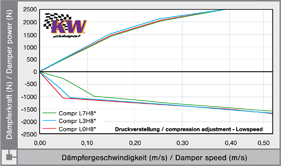

Graphic representation of the relation from damper speed (m/s) to damping force (N) when adjusting the compression damping in low-speed range.

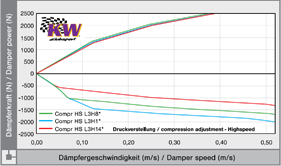

Graphic representation of the relation from damper speed (m/s) to damping force (N) when adjusting the compression damping in high-speed range.

Compression Adjustment with 6 Clicks in Low-Speed

and 14 precise Clicks in High-Speed Range

To make sure you are leading the pack on the Nordschleife, the KW Clubsport 3-way coilovers were developed from feedback from our worldwide pool of performance enthusiasts and fine tuned by our experienced engineers.

Racing Technology for Everyone

The vehicle specific setup of the KW 3-way dampers are developed through numerous test runs on the Nordschleife and the KW 7-post chassis dynamics test rig. The TVCLH-A (Twin Valve Compression Low High - Adjustable) technology allows further adjustment to accommodate your wheel loads, vehicle weight, and change in body stiffness due to a strut bar, bolt in roll bar, welded roll cage. Similar to the KW Competition racing suspensions used in international motorsports the KW 3 way damper allows you to adjust the compression damping separately in the low speed and high speed range.

Comfort, Sport or Maximum Performance - The Decision is in your Hands!

The click adjustment on the patented KW valve occurs directly on the external reservoir. The purple adjustment wheel allows you vary the vehicle specific low speed compression damping from the base setup, which is determined by our experienced engineers with six precise clicks. With the gold adjustment wheel you can adjust the high speed compression damping with 14 precise clicks from the recommended base setup. The low speed range of the compression damping affects the damping during lower piston rod speeds (max. 0,2 m/sec). The high speed compression damping affects all faster speeds of the piston rod.

While driving over rumble strips or after sudden jumps, the piston rod immerses faster, especially on different and uneven asphalt surfaces like those usually found around the Nürburgring Nordschleife. As an active sports car driver, the KW 3-way dampers offer you the possibility to decide exactly when the low-speed compression and the high-speed damping become active thanks to their broad range of adjustment.

- Separate and independent damping force adjustment for the rebound and compression in low-speed and high-speed

- Basic setup from factory with adjustment range in +/- direction

- Rebound damping: comfortable setting with 16 precise clicks

- Low-speed compression damping: with 6 precise clicks

- High-speed compression damping: with 14 precise clicks

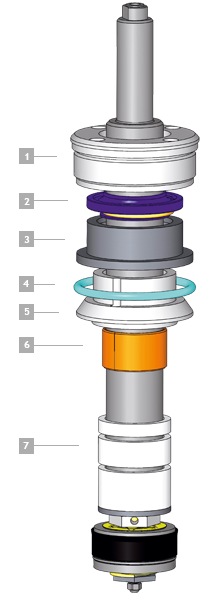

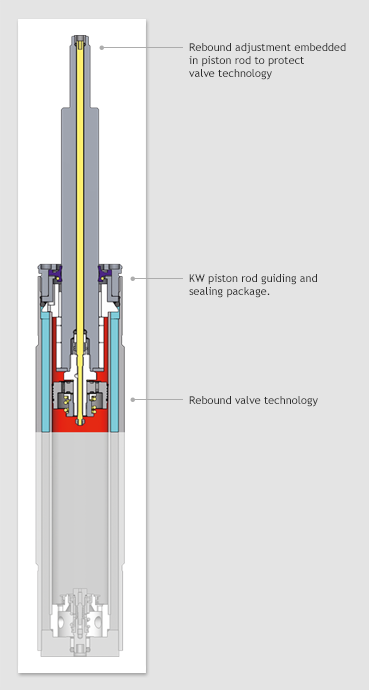

KW Piston Rod Guide and Sealing Package

Our modular sealing system exceeds OEM quality standards. It can be easily opened and allows maintenance of the valve technology or rod and piston.

- High tensile aluminum top sealing cap

- Self-lubricated special NBR seal package

- Clamp sleeve

- Temperature-resistant viton O-rings

- Guide bushing with bleed hole

- Special DU Metal-Polymer anti-friction plain bearings

- Polyamide rebound spacers